Candidate of Technical Sciences Yelemes D.Y., Kasym D.S ., Kalieva A.D.

D. Serikbayev East Kazakhstan state technical university

THE LOGISTICAL ANALYSIS OF TECHNOLOGICAL SCREENING PROCESS OF THE LOOSE MATERIAL

Machines for screening – form uniform system with a sifted material «a working (sifting) surface – a processed material». As a result of machine working body action there are typical mehano-physical processes of loose materials division in system elements, which make independent unit of the first step in hierarchical structure of building, metallurgical, and other kinds of manufactures. Detailed elaboration of this unit to level of the elementary effects and the phenomena makes it possible to consider screening process as a difficult mehano-physical system. Following the technique of prof. V.V. Kafarov’s school [2], it is possible to carry out the analysis of mehano-physical system structure.

Logistization of technological repartition has character of continuous process through realization of logistical management functions: "planning", "coordination", "control", "the motivation" which operations are closely interconnected with each other (Picture 1).

At interaction of a working (sifting) surface with a processed material the density and the drain of energy arriving from a power-plant concentrates in a plane of their contact. The brought energy creates the intense-deformed condition, continuity and volume static balance violation in a work material. It is accompanied by the transfer of elementary substance volumes from one steady state to another, by formation of shear and slip plains on interfaces in the damaged structure of a work material and on the surfaces of movable operating element. Macrolevel is characterized by the physical-mechanical effects inside the system. Their character is defined by the surface forces which operate in local volumes, and in interaction forces between and dispersions bearing phase (Static lift, Stoksov’s force of a friction, Zhukovsky and Magnusa forces, and others) [3].

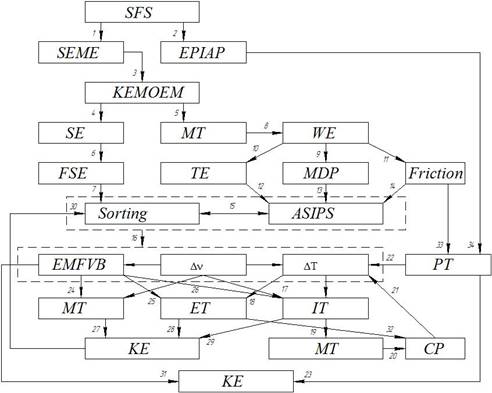

The set of effects at macrolevel is defined by the intensity of mehano-physical system which depends on hydro mechanical streams and their character that is directly set by structural features and screens operating regime (SFS) (Fig. 1):

Fig. 1. Basic model of the logistical analysis of screening process function

Design features of the device define links 1,2 – a supply external mechanical energy (SEME) to the movable operating element (MOE) and the thermal, electric, magnetic and other disturbances that are brought with entering parameters for intensification or activization process (EPIAP).

The brought external mechanical energy to MOE is transformed during working process to other kinds [3]: kinetic energy of movable operating element motion (KEMOEM), that provides mass transfer in system (MT) and a solid phase sorting (SE).

In a qualitative sense power expenses can be divided into two streams:

- The energy that is spent for sorting. The reasons of it are primary effects (SE and MT) and their derivatives, free superficial energy formations (FSE), sorting of a sifted material;

- Energy (WE) consumed in the course of work first of all is a power supply of grains (pieces) material division direct process (MDP) and thermal energy dissipation (TE) which is spent for an external friction, and on accumulation in the structurally-caused internal pressure system (ASIPS).

The products formed in a result of sorting are undergoing to secondary transfer mechanism of mass transfer (MT), energy (ET) and impulse (IT) – (links 17, 18)), supporting phase and separate particles. Temperature D Ò and high-speed D n nonequilibrium influence on mass transfer, impulse and energy parameters. Purely thermal efficiency is insignificant, therefore it is necessary to consider effect of D Ò influence as facilitating mechanical division, change processes of steam wetness and the nature of thermal energy dissipation.

M omentum streams (MS) generate mechanical trajectories of system movement ( Ò M), in other words current lines (link 19), possibility of their collision ( Ñ P) and the subsequent change of momentum streams and energy in the material – links 20 and 21.

Change of traffic conditions and character of hydrodynamic structure of changeable material layers , of their trajectory (MT) and processing time (PT) influences on quantitative and qualitative characteristics of production (QQCP).

Considering the screening process of the loose material as a difficult mehano-physical operation , it is necessary to take into account that efficiency of macroeffects depends on formation of a field of temperatures on the scale of the device, electric, magnetic, vibrating and other clutters, and employees for screening process intensification [4; 5].

Each level of technological processes structure can be analyzed by the stated technique and can be described by the corresponding form of mathematical model. Thus particularly proceeding processes can be detailed of the particular form of record and can be considered as elementary processes in the conditions of concrete accepted restrictions.

The list of references :

1. Verigin U.A. Theoretical aspects of building mortars and concreate mixing, and their mathematical description / U.A.Verigin // Automation and improvement of technological and concrete mix preparation equipment. – M., 1978. – P. 61–65.

2. Kafarov V.V. System analysis of chemical technology processes. Strategy bases / V.V. Kafarov, I.N. Dorokhov. – M.: Science press, 1976. – 508 p.

3. Verigin U.A. Basis of theory and fine-dispersed medium technology perfection, machines and the equipment for reduction of materials / U.A. Verigin; Schools of thought and directions of the Altay state technical university of I.I. Polzunova . Novosibirsk: the Science. – 2003. – P. 138–143.

4. Verigin U.A. The calculation problems of thin media vibration milling / U.A. Verigin, A.V. Sartakov // High schools. Building. – 2001. – ¹ 7. – Ð . 112–115.

5. Surashov N.T. Spiral vibrational sifters / N.T. Surashov, D.E. Yelemes, A.V. Vavilov. – Almaty: Kazakh National Technical University, 2010. – Ð . 126.