Vashchenko M. A.

National

Technical University of Ukraine "Igor Sikorsky Kyiv Polytechnic Institute", Ukraine

Studying the electrical drive, we can often hear the phrase an AC engine

with an asynchronous-valve cascade. The AVC is easily included in

the system of automatical the monitoring of the production process. This stage

significantly increases interest in electrical drives, capable of engine speed monitoring.

It is used in frame for high-power fans, pumps and compressors. One of the main

advantages of this stage is the reduction of electricity intake. That is due to

the fact that in large enterprises energy saving is one of the most grave criteria.

Another big advantage is advance of the qualitative of products achieved by the

energy recuperation slip of the AC engine.

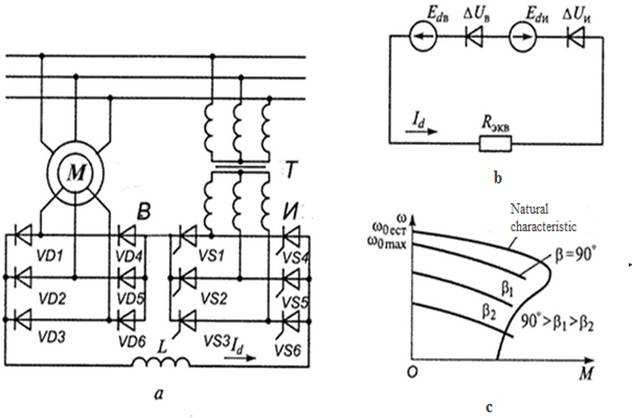

Fig. 1. The electrical outline (a), the outline

for replacing the rectified current outline (b), the mechanical characteristics

(c)

Fig. 1. The electrical outline (a), the outline

for replacing the rectified current outline (b), the mechanical characteristics

(c)

The figure

shows a diagram of the AVC that provides the engine operation. If we look at

the specifications, we will see that the speed lower than the synchronous

engine’s speed is continuously adjustable down to the natural characteristics. If

you look at the startup circuit, you will see an equivalent resistor.

In addition, the

converter used at the valve phase is

only rated for power proportion to this control range. At the same time, in group

with frequency control, the converter participates in the creation of a magnetic

flow, and when designing it, it is necessary to take into account the total

power of the drive.

The simplest

scheme of the valve stage is a outline with an intermediate DC circuit and a

gate converter. In the AVC, the energy of sliding is first converted into immediate

current energy, and then by the inverter UZ2 into the AC energy of a fixed

frequency. The transformer T is designed to match the output voltage of the

inverter with the mains voltage. To control the speed of the AVC, it is

necessary to change the value of the inverter’s electromotive force on the DC

side by changing the opening angle of the thyristors (b).

In this

electrical drive, with a simple regulating device, a wide speed range and torque

monitoring is provided for the engine, and high energy values are achieved by

transferring energy from the motor rotor outline to the capacity supply

network.

The energy

given by the cascade pollutes the network with higher harmonics, which

adversely affect the work of a number of consumers. And, finally, the largest

capital and estimated costs required for the equipment for driving the cooling fans

according to the AVC scheme exclude its request in the coming years to the

drives of the cooling fans.

Thus, in the

proposed AVC, a wide speed range and torque monitoring is provided, with the

motor's sliding energy from the rotor circuit being returned to the alternate

current outline across an optocoupler bridge converter operating in an inverter

mode, which provides energy saving. The proposed monitoring system is simple and reliable; mechanical characteristics are

favorable for hoisting and transport mechanisms.

One of the

biggest drawbacks of this stage is its low the force factor and the cost of the

converter that increases the cost of the drive. In terms of amount and value of

the equipment, there is a certain relationship. The greater the volume, the

greater the cost of the equipment, so advantageous to use the

asynchronous-valve cascade with little regulation of the engine speed.

The asynchronous-valve

cascade provides the following types of protection and interlocks from:

- external and

internal short outlines;

- inadmissible

by magnitude and duration of the overload currents of the power outline

elements and the powered motors (time-current protection);

- violation of

the cooling system;

- increased and

reduced supply voltage;

- exceeding the

speed of the engine;

- an

unacceptable reduction in the tension of own needs;

- malfunction

of power supplies;

- blocking the

activation when there are emergency and warning signals.

The applied

control scheme for regulating the speed of movement is based on a change in the

additional resistance in the rotor circuit, which causes large losses of the electric

power consumed by heating the resistors and a low range of shaft speed

regulation.

Mathematical

models of open and closed systems of the AVC

allow conduction of the research of dynamic processes and static

characteristics of the electrical drive under various constructions of the

power part and automatical monitoring systems.

A system for

starting an asynchronously valve stage is designed to smoothly control the

voltage at the output of a controlled rectifier connected to the windings of

the motor rotor as a function of the electromotive force of the rotor winding,

which expands the functionality of the asynchronously valve stage. Thus, using

the AVC by different companies, we can

achieve energy savings and get an manageable electrical drive.