Samartsev

I.

V.

NEURAL NETWORK BASED SPEED CONTROL

FOR A DC MOTOR

Abstract. This paper introduces a new concept of

Artificial Neural Networks (ANNs) in estimating speed and controlling a

separately excited DC motor. The neural control scheme consists of two parts.

One is a neural estimator, which is used to estimate the motor speed. The other

is a neural controller, which is used to generate a control signal for a

converter. These two networks are developed by Levenberg-Marquardt back

propagation algorithm. A standard three-layer feed forward neural network with

sigmoid activation functions in the input and hidden layers and purelin in the

output layer is used. Simulation results are presented to demonstrate the

effectiveness and advantages of the control system of the DC motor with the ANNs

in comparison with the conventional control scheme.

Nowadays, the fields of an electrical power system

control in general and a motor control in particular are gaining momentum. The

new technologies are emerging for control scheme. One of these new technologies

is Artificial Neural Networks (ANNs) that are based on the operating principle

of a human being nerve neural. This method is applied to control the motor

speed [1]. Inverting forward ANNs with two input parameters for an adaptive

control of the DC motor [4] is used. However, these researches were not

interested in the ability of forecasting and estimating the DC motor speed. The

ANNs are applied broadly because of the following special qualities:

1. All

the ANNs signals are transmitted in one direction, the same as in an automatically

control system.

2. The

ability of the ANNs to study the sample.

3. The

ability to create the parallel signals in analog as well as in a discrete

system.

4. The

adaptive ability.

With the special qualities mentioned above, the ANNs

can be trained to display the nonlinear relationships that the conventional

tools could not implement. It is also applied to control complicated electromechanical

systems such as DC motor and synchronous machines [5]. To train the ANNs, the

input and output datasheets are to be determined first, and then the ANNs’ net

is being designed by optimizing the number of hidden layers, and neurals of

each layer, the number of neurals of each layer, as well as the input/output

number and the transfer function. The following is to find the ANNs net

learning algorithm. The ANNs are trained to rely on two basic principles:

supervisor and unsupervisor. According to a supervisor, the ANNs study the

input/ output data (targets) before being used in the control system. In this

paper, the new ANNs’ application in speed estimating and controlling a separately

excited DC motor is presented. The motor speed is controlled by a forecasting

method and a forecasting task, which the ANNs undertake from the terminal

voltage parameter, armature current, and a reference speed.

II. DC MOTOR CONTROL MODEL WITH ANNS

The DC motor is the obvious proving ground for

advanced control algorithms in electric drives due to the stable and straightforward

characteristics associated with it. It is also ideally suited for trajectory

control applications as shown in the reference [1-3]. From a control systems’

point of view, the DC motor can be considered as a SISO plant, thereby

eliminating the complications associated with a multi-input drive system.

Conventional control systems of the DC motor:

There are different methods to synthesize control

systems of the DC motor. The ANNs authors have presented a conventional control

system of the DC motor, where a current regulator and a speed regulator are

synthesized by Bietrage-optimum to reduce the over-regulation [6].

In the conventional model, current and voltage sensors

are very important elements that play the main role during the regulation of

speed alongside with a current regulator and a speed regulator. For the speed control

of the DC machine, a conventional feedback control logic approach is observed

to be lower in accuracy due to direct sensor measurements. The approach is to

be developed for selecting the speed parameters and providing accurate

controlling to the driving circuitry. For the realization of such a controlling

approach, in this paper, a neural network based control strategy is proposed.

The developed approach is briefed in the following sections.

The control system of the DC motor using ANNs:

A neural network is a generalized approach to making

the learning algorithm and a decision for accurate control operation in various

applications. The approach of a neural network basically works on the provided

priories’ information and makes a suitable decision for a given testing input

based on the provided training information. This approach is analogous to the

human controlling approach where all the past observations are taken as the

reference information and are used as a decision variable. To obtain such

estimation in the current DC motor controlling approach, the current DC motor

drives are to be improved using such a learning approach. In this paper, a dual

level neural network approach is designed for DC machine speed control. A dual

level modelling provides faster training and converging as compared to a single

level neural modelling. For the realization of a dual level neural modelling, a

two-neuro architecture, namely ANN-control and ANN-train, is proposed.

The 2 models of the control system of the DC motor

using the ANNs are built with the ANN-train and ANN-control unit where the

network is developed to emulate a function: ANN-train to estimate the speed,

ANN-control to control the terminal voltage.

The structure and the process of ANNs’ learning.

The ANNs are trained to emulate a function by

presenting it with a representative set of input/output functional patterns.

The back-propagation training technique adjusts the weight in all connecting

links and thresholds in the nodes so that the difference between the actual

output and target output are minimized for all given training patterns [1]. In

designing and training an ANN to emulate a function, the only fixed parameters

are the number of inputs and outputs to the ANN, which are based on the

input/output variables of the function. It is also widely accepted that the maximum

of two hidden layers is sufficient to learn any arbitrary nonlinearity [4].

However, the number of hidden neurons and the values of learning parameters,

which are equally critical for satisfactory learning, are not supported by such

well-established selection criteria. The choice is usually based on experience.

The ultimate objective is to find a combination of parameters which gives a

total error of required tolerance a reasonable number of training sweeps [1, 2, 3].

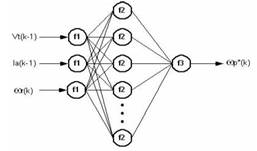

f1: tansig;

f2:tansig; f3: purelin

Fig 1. Structure of ANN-training

The ANN1 and the ANN2 structures are shown in Fig4, and Fig5. It

consists of input layer, output layer, and one hidden layer. The input and

hidden layers are tansig-sigmoid activation functions, while the output layer

is a linear function. Three inputs of the ANN are reference speed ωr(k),

terminal voltage Vt(k-1), and armature current ia(k-1). And output of ANN1 is

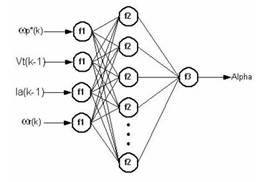

an estimated speed ωp*(k). The ANN2 has four inputs: reference speed

ωr(k), terminal voltage Vt(k-1), armature current ia(k-1), and estimated

speed ωp*(k) from ANN-1. The output of the ANN is the control signal for

converter Alpha.

f1: tansig; f2:tansig; f3: purelin

Fig 2. Structure of ANN model

The ANNs are trained off-line using inputs patterns of ωr

(k), Vt (k), ia (k) - for ANN1, and of ωr

(k), Vt (k), ia (k), ωp*(k) for ANN2.

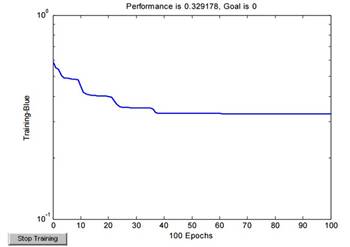

The training program of the ANN is written in the Neural Network of

Matlab program under m-file; and it uses the Levenberg – Marquardt back

propagation. There are no references that mention the optimal number of neural in

each layer, so collecting the neural networks becomes more complicated. In

order to choose the optimal number of neurals, the neural network is trained by

the m-file program, reducing the number of neurals in the ANNs’ hidden layer

until the learning error can be accepted.

The ANNs and the training effort are briefly described by the following

statistics.

Table 1

The results of the ann

training

|

Network |

ANN1 |

ANN2 |

|

Number of input |

3 |

4 |

|

Number of output |

1 |

1 |

|

Number or hidden layer |

1 |

1 |

|

Number of hidden neurons |

3 |

4 |

|

Number of training patterns |

1215 |

1215 |

|

Number of training sweeps |

5000 |

5000 |

|

Learning error |

1e-7 |

1e-8 |

III.

SIMULATION RESULTS

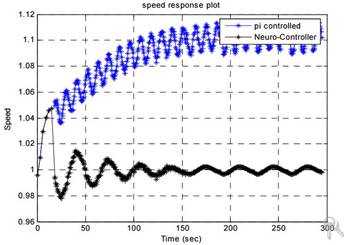

To simulate the conventional control system and the control system with the

ANNs, a Simulink/Matlab program with the toolbox of Neural-network is used. The

DC motor, which is used in models has the following parameter: 5HP, 240V, 1750

RPM, field 150V, J=0.02215 Nm2, KF=1.976 NmA-1, B=0.002953 Nms, Ra=11,

La=0.1215 H. To compare the results of two control system schemes, different

operating modes of the DC motor are considered.

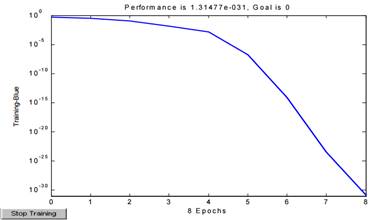

Fig 3. Training observation of NN designed

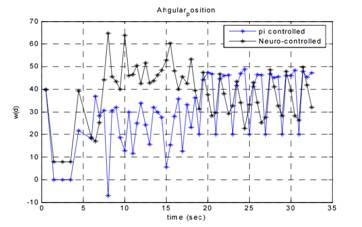

Fig 4. Reference parameters

of the DC motor are the same. At reference = 0.1

a)

b)

c)

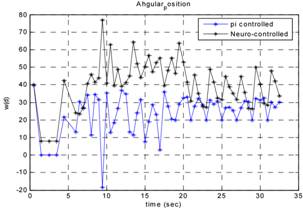

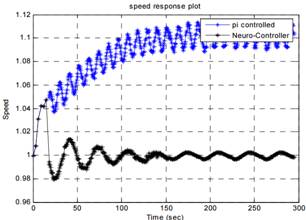

Fig 5. (a,b,c) - Reference parameters of the DC motor

are different.

IV.

CONCLUSION

The

DC motor has been successfully controlled using an ANN. Two ANNs are trained to

emulate functions: estimating the speed of the DC motor and controlling it.

Therefore, the ANNs can replace speed sensors in control system models. Using the

ANNs, there is no need to calculate the parameters of the motor when designing

the system control. It has shown appreciable advantages of a control system

using the ANNs above the conventional one, when the parameter of the DC motor

is variable during the operation of the motors. The satisfied ability of the

system control with the ANNs is much better than the conventional controller. The

ANNs application can be used in adaptive controls for machines with complicated

loads.

The list of

references:

1. Weerasoorya S., Al-Sharkawi M. A. Identification and control of a DC Motor using

back-propagation neural networks / S. Weerasoorya, M. A. Al-Sharkawi. – IEEE transactions on Energy Conversion. – 1991. – Vol. 6. – No. 4. – Ðp. 663–669.

2. Psaltis D., Sideris A., Yamamura A. A. A Multilayered Neural Network Controller / D. Psaltis, A. Sideris, A. A. Yamamura. – IEEE Control System Magazine. – 1988. – Ðp. 17–20.

3. Kosko B. Neural Networks and Fuzzy Systems / B. Kosko. – Prentice-Hall International Inc. – 1992.

4. Levin E., Gewirtzman R., Inbar G. F. Neural Network Architecture for Adaptive

System Modellinggand Control / E. Levin, R. Gewirtzman, G. F. Inbar. – Neural Networks.

– 1991. – No. 4 (2). – Ðp. 185–191.

5. Scott G. M. Knowledge-Based Artificial Neural

Networks for Process Modelling and Control / G. M. Scott. – PhD. Thesis,

6. German-Gankin S. G. The computing

modeling for power electronic systems in Matlab / S. G. German-Gankin. – 2001.

7. Rasid. High performance nonlinear MIMO field weakening controller of a

separately excited dc motor / Rasid. – Electric Power Systems Research. – 2000. – Vol. 55, issue 3. – Ðp. 157–164.

8. Nabil A. Ahmed Modeling and

simulation of AC-DC buck-boost converter fed dc motor with uniform PWM

technique / A.

Ahmed Nabil. – Electric

Power Systems Research. –2005.

– Vol.

73, issue 3. – Ðp. 363–372.

9. Figueroa J., Brocart C., Cros J., Viarouge P. Simplified

simulation methods for poly phase brushless DC motors. Mathematics and Computers in Simulation

/ J. Figueroa, C.

Brocart, J. Cros, P. Viarouge. – 2003. – Vol. 63, issues 3-5. – Ðp. 209–224.

10. Santana J., Naredo J. L., Sandoval F.,

- Charles I. Ume, Ward J., Amos J. Application of

microcontroller for speed control of a DC motor / I. Ume Charles, J. Ward, J. Amos // Journal of Microcomputer Applications.

– 1992. – Vol. 15, issue 4. – Ðp. 375–385.